- Why ULC?

- R&D Services

Research & Development

MenuLeading Innovation. Driving Results.

- Industries

- Products & Services

Field Services

MenuProducts

MenuEmissions Recovery

Menu - Company

Service

In-pipe Intelligence. Industry Expertise.

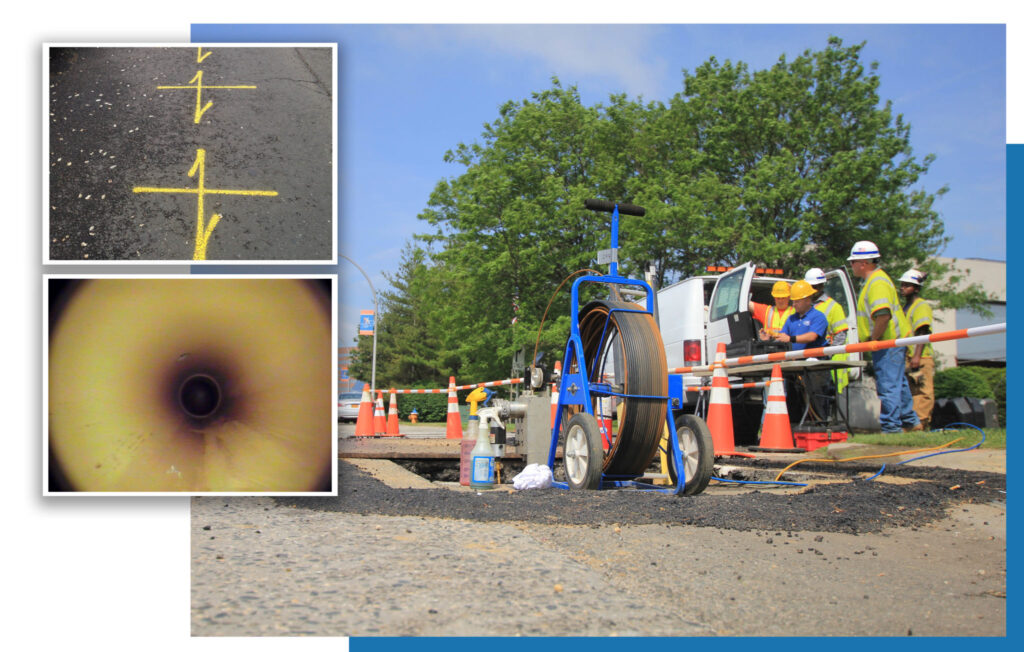

The real-time intelligence delivered by ULC’s live gas main camera and crawler inspection services helps US and UK gas distribution utilities reduce risks, improve efficiency, lower costs and resolve a wide range of operational challenges.

ULC Technologies works with some of the largest gas networks to conduct live gas main inspection cctv services and deliver detailed reporting, accurate mapping and real-time video.

Live Gas Main Inspection

Key Benefits

Experienced Field Crews

Our operator qualified crews bring years of experience and expertise in live gas distribution main cctv inspection to deliver high-quality assessments, feature identification, accurate reporting and detailed mapping.

Leading Technology

Designed and engineered in-house for safe and reliable assessment of live gas mains, ULC’s range of purpose-built camera and crawler systems enable real-time inspection and locating of the gas main and features visible from inside the pipe.

Industry Expertise

ULC’s team manages large scale inspection and locating programs to support post–storm emergency response, gas main replacement damage prevention and mapping to improve efficiency and safety while reducing costs.

Live Gas Main Inspection

Our Technology

M1 Crawler

Large VGC

Small VGC

PRX250 System

M1 Crawler

Diameter Range: 24″-48″ / 609+mm | Applications: Cast Iron, Steel

The successful delivery of insertion projects involving large diameter medium pressure mains are often complicated by internal seals and obstacles which may prevent the insertion process or damage newly inserted PE pipe. The M1 Live Gas Main Inspection Crawler System navigates past these internal seals and other obstacles to deliver comprehensive visual pre-insertion data that minimizes excavation, improves project efficiency and enables more accurate project cost projections.

Large VGC

Diameter Range: 18″-48″ / 450+mm | Applications: Cast Iron, Steel

The Large Variable Geometry Crawler (VGC) provides gas utilities with live, high-resolution video inspection of large diameter steel or cast iron gas mains ranging in diameter from 18″ up to 48″. Using the Large VGC, utilities can assess the conditions of their mains as well as locate cracks, damaged pipe, unknown branches, service tees, valves, fittings and water intrusion or debris. Pipelines can be inspected without the hassle and costs of taking a main out of service.

Small VGC

Diameter Range: 12″-16″ / 315-400mm | Applications: Plastic, Cast Iron, Steel

ULC Technologies’ Small Variable Geometry Crawler (VGC) provides gas companies with live, high-resolution video inspection of medium diameter steel or cast iron gas mains. Using the Small VGC, gas companies can assess the conditions of their mains as well as locate cracks, damaged pipe, unknown branches, service tees, valves, fittings and water intrusion or debris. This inspection is performed while the main remains live without any interruptions in gas service.

PRX250

Diameter Range: 4″-12″ / 101-315mm | Applications: Plastic, Cast Iron, Steel

The PRX250 Live High Pressure Gas Main Camera Inspection System is the most comprehensive, innovative live gas main camera system to provide gas networks with the highest quality, most cost effective and reliable pipeline inspection possible. The use of our PRX250 system is proven to provide significant cost savings, improved safety, increased efficiency and higher customer satisfaction.

Live Gas Main Inspection

What We Do

Eliminate 3rd Party Damage

Using our specialized equipment, our teams pinpoint the exact location of your mains along with all pipeline features—even those not traceable by traditional locating methods. The resulting mark out provides the road map construction crews need to ensure project efficiency and safety. ULC manages large scale programs in conjunction with cast iron replacement programs and Aldyl-A replacement programs.

Pre Rehabilitation Mapping

Prior to gas main rehabilitation using CISBOT, lining and insertion, our crews identify and mark out features such as offsets, drip pots, valves and protruding services that might delay the project, increase project costs or even damage material during the rehabilitation process. Data delivered by ULC Technologies improves project planning, helps determine more accurate project costs and improves go / no-go decision making.

Identify, Inspect & Locate Features

Utilities have an increasing need to identify and inspect features in gas mains. ULC’s crews provide detailed video and mapping of features such as couplings, stub services, tees and valves. From within the gas main, our camera and crawler systems can deliver a detailed visual assessment of PE pipework to identify imperfections that may not be visible from outside the pipe.

Unlocatable PE

ULC Technologies is helping utilities resolve challenges around unlocatable PE gas mains by providing a means of locating and mapping the main and all features visible from within the pipe. Our crews provide pinpoint accurate markout for excavation crews or accurate utility mapping so utilities can update mapping.

Hear From Real Customers

Clint W.

– Chief Construction Inspector, Orange & Rockland Utilities

Before we excavate for replacement of Aldyl-A pipe, we always call ULC to help us avoid third party damages in the field. We won’t dig until ULC marks the main using their long range cameras. Their marks are spot-on, which means fewer holes in the street for our community.

Brett Fisher

– Supervisor of Construction, Elizabethtown Gas

Before we brought in ULC, we had to rely on old records and some of the curb lines have changed or streets have widened, making it challenging to locate the stubs. In-Pipe Locating is a good program to bring in to help us locate the stubs and possibly prevent damages when we’re installing our new gas main.

Related Projects

Explore What We've Done

Field Operations

|

U.S.

Ready to Talk?

Contact our team to discuss your next project or learn more about our live gas main inspection services.