- Why ULC?

- R&D Services

Research & Development

Leading Innovation. Driving Results.

- Industries

X-ID CROSS BORE DETECTION SERVICES

Our patented acoustic technology detects cross bores from within gas mains and services. Learn MoreLIVE GAS MAIN INSPECTION

We are leaders in the deployment of camera and crawler systems into live gas mains. Learn More

PORTABLE EMISSIONS RECOVERY

Our drawdown compressor technology helps gas distribution utilities reduce emissions. Learn More

AIM: AI-POWERED UTILITY MAPPING

Using vehicle-mounted cameras along with AI and Machine Learning to map electric distribution poles and pole-mounted assets. Learn More

CIRCUIT BREAKER RACKING ROBOT

Breaker Racking RobotAutonomous mobile robot designed to rack and unrack large breakers within substations. Learn More

ELECTRIC CONDUIT INSPECTION

Our field service teams provide video inspection of conduits prior to cable pulls to identify obstructions and pinpoint damages. Learn More

Machine Learning for Jacket Foundation Inspection

ULC used machine learning to enable more efficient inspection of jacket foundations at the Block Island Wind Farm. Learn More

Electrical Conduit Inspection Services

Our field teams provide internal inspection of conduits to pinpoint obstruction and damage prior to cable pulls. Learn More

Robotics & Technology Development

We work with leading energy companies to develop, commercialize, and deploy robotic systems and technologies that support the construction, maintenance, and inspection of infrastructure. Learn More

- Products & Services

Field Services

Products

Live Gas Main Inspection Cameras

Emissions Recovery

- Company

Project Overview

Industry: Gas Distribution

Location: Edinburgh, Scotland

Client: SGN

Main Diameter: 24″ Cast Iron, Low Pressure

Main Length: 600m

Business Areas Addressed:

- Gas Remediation

- No disruption to customers’ gas supplies

- Minimised disruption to traffic, keeping the road open throughout the project

- Reduced operational costs and carbon emissions

Project Description

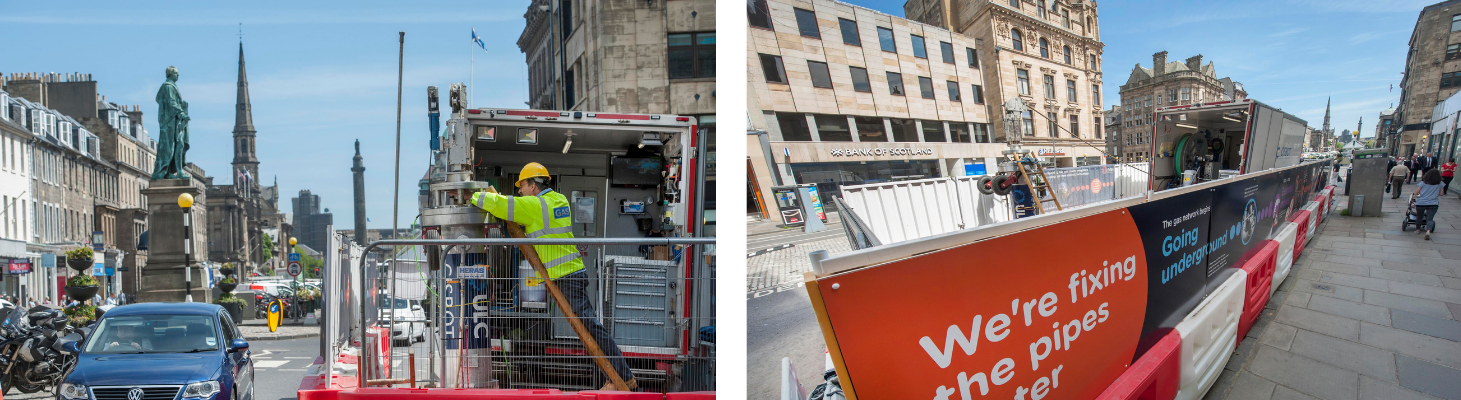

When a large diameter cast iron gas main along George Street in Edinburgh, Scotland was in need of rehabilitation, ULC Robotics launched its CISBOT robotic technology for gas network, SGN. The robotic technology was deployed into a live gas main to renew 600m of pipe that delivers gas to business and residents along the centre city street.

Because the project was in such a densely populated area, it was critical that CISBOT’s joint sealing work allowed gas service to stay turned on to the multiple businesses and shops, and the site footprint remain compact and clean to allow traffic to flow smoothly throughout the six week project.

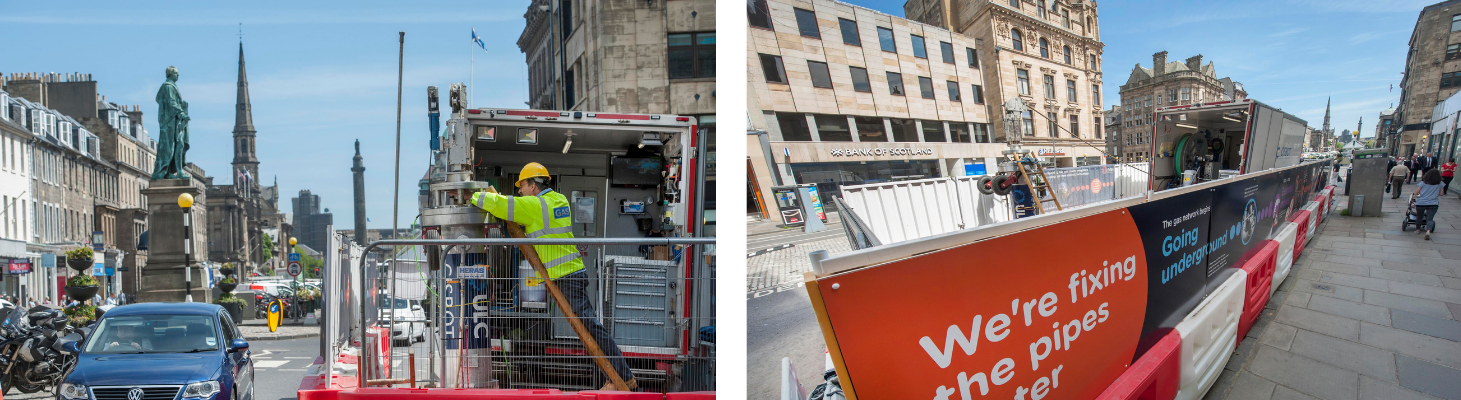

With just two excavations in the road, CISBOT’s renewed more than 200 joints and 96% of the work was invisible to the public.

Challenges

George Street in Edinburgh, Scotland is one of the city’s most high profile and central locations. With multiple restaurants, specialty shops and businesses lining the street it was imperative that gas service remained turned on and that foot and vehicle traffic flowed smoothly while the gas main was being rehabilitated by CISBOT.

ULC Robotics’ CISBOT launches through a small excavation in the street into 100 percent live gas cast iron mains to seal leaking joints and prevent new leaks from forming. The non-intrusive work performed by CISBOT allowed gas service to remain online, traffic was able to flow smoothly and the project was completed successfully with 96% of the work unseen by the public.

“In George Street, we’ll be carrying out maintenance on exactly 600m of gas pipe. The work will take around six weeks, however the use of this technology will make a difference in minimising disruption, as we will only need to make two excavations in the road. In fact, 96% of our work will be unseen as it will take place under the ground.”

Matt F., Team Manager, SGN

Project Goals

By working with ULC, SGN achieved multiple goals by utilising CISBOT to renew the large diameter cast iron gas main along George Street. The innovative technology reduced the amount of time and excavations needed to renew the pipeline.

Compared to traditional replacement or rehabilitation methods which would have closed a portion of the street and turned off gas service to customers, CISBOT allowed SGN to keep the the high profile and heavily trafficked, George Street, open to the public and gas service remained turned on.

CISBOT’s work also reduced operational costs, cut greenhouse gas emissions and increased the satisfaction of their customers by reducing the public disruption that is often cause while conducting roadworks.