- Why ULC?

- R&D Services

Research & Development

Leading Innovation. Driving Results.

- Industries

X-ID CROSS BORE DETECTION SERVICES

Our patented acoustic technology detects cross bores from within gas mains and services. Learn MoreLIVE GAS MAIN INSPECTION

We are leaders in the deployment of camera and crawler systems into live gas mains. Learn More

PORTABLE EMISSIONS RECOVERY

Our drawdown compressor technology helps gas distribution utilities reduce emissions. Learn More

AIM: AI-POWERED UTILITY MAPPING

Using vehicle-mounted cameras along with AI and Machine Learning to map electric distribution poles and pole-mounted assets. Learn More

CIRCUIT BREAKER RACKING ROBOT

Breaker Racking RobotAutonomous mobile robot designed to rack and unrack large breakers within substations. Learn More

ELECTRIC CONDUIT INSPECTION

Our field service teams provide video inspection of conduits prior to cable pulls to identify obstructions and pinpoint damages. Learn More

Machine Learning for Jacket Foundation Inspection

ULC used machine learning to enable more efficient inspection of jacket foundations at the Block Island Wind Farm. Learn More

Electrical Conduit Inspection Services

Our field teams provide internal inspection of conduits to pinpoint obstruction and damage prior to cable pulls. Learn More

Robotics & Technology Development

We work with leading energy companies to develop, commercialize, and deploy robotic systems and technologies that support the construction, maintenance, and inspection of infrastructure. Learn More

- Products & Services

Field Services

Products

Live Gas Main Inspection Cameras

Emissions Recovery

- Company

Service

Direct Assessment Of Cased Pipeline Segments

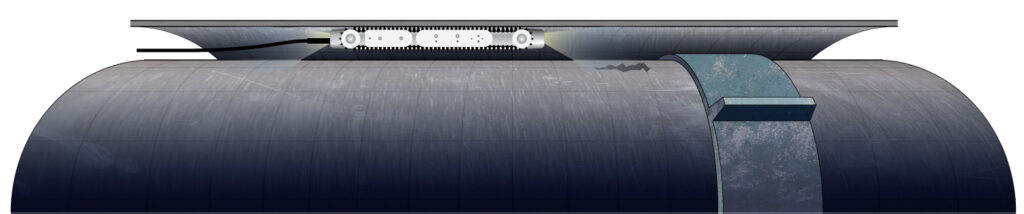

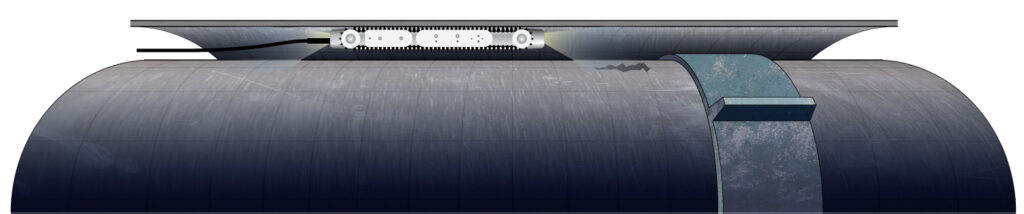

Using our Magnetic Cased Crawler (MCC) our team provides pipeline operators with a live, high resolution inspection of cased pipeline segments. The remote controlled, tethered robot allows our team to directly assess cased pipe from within the annular space to locate damaged spacers, shorts and determine the condition of carrier pipeline coating. It can also verify if debris or water have infiltrated the casing, acquire spot wall thickness measurements and measure the temperature and humidity from within the annulus.

Robotic Cased Pipeline Inspection

How It Works

Robotic Cased Pipeline Inspection

Key Benefits

Real-Time, High Resolution Video

A real-time feed of video from the crawler can be viewed during the inspection and provided on DVD for post-inspection review.

Ultrasonic Thickness Measurements

Data can be measured through various types of coatings including coal tar TGF-3, enamels and epoxies and PE two-layer coatings such as PRITEC.

Advanced Video Measurement

Debris, damage and pipeline features are accurately measured using specialized software.

Ultra-Compact Crawler

The MCC measures 1″ tall and is capable of traveling in tight annular spaces and past common spacer types and debris.

Additional Sensor Data

Sensors can measure circumferential location as well as the temperature and humidity of the annular space.

Data and Reporting

In addition to providing recorded video, our team also produces detailed reports that help you better understand the condition of your cased pipeline.

Related Projects

Explore What We've Done

|

Ready to Talk?

Contact our team to learn more and discuss your casing inspection needs.