- Why ULC?

- R&D Services

Research & Development

Leading Innovation. Driving Results.

- Industries

X-ID CROSS BORE DETECTION SERVICES

Our patented acoustic technology detects cross bores from within gas mains and services. Learn MoreLIVE GAS MAIN INSPECTION

We are leaders in the deployment of camera and crawler systems into live gas mains. Learn More

PORTABLE EMISSIONS RECOVERY

Our drawdown compressor technology helps gas distribution utilities reduce emissions. Learn More

AIM: AI-POWERED UTILITY MAPPING

Using vehicle-mounted cameras along with AI and Machine Learning to map electric distribution poles and pole-mounted assets. Learn More

CIRCUIT BREAKER RACKING ROBOT

Breaker Racking RobotAutonomous mobile robot designed to rack and unrack large breakers within substations. Learn More

ELECTRIC CONDUIT INSPECTION

Our field service teams provide video inspection of conduits prior to cable pulls to identify obstructions and pinpoint damages. Learn More

Machine Learning for Jacket Foundation Inspection

ULC used machine learning to enable more efficient inspection of jacket foundations at the Block Island Wind Farm. Learn More

Electrical Conduit Inspection Services

Our field teams provide internal inspection of conduits to pinpoint obstruction and damage prior to cable pulls. Learn More

Robotics & Technology Development

We work with leading energy companies to develop, commercialize, and deploy robotic systems and technologies that support the construction, maintenance, and inspection of infrastructure. Learn More

- Products & Services

Field Services

Products

Live Gas Main Inspection Cameras

Emissions Recovery

- Company

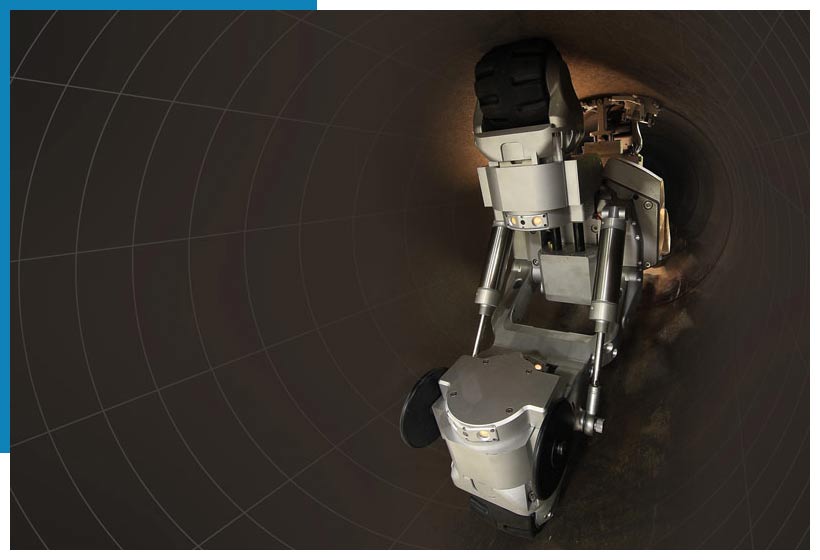

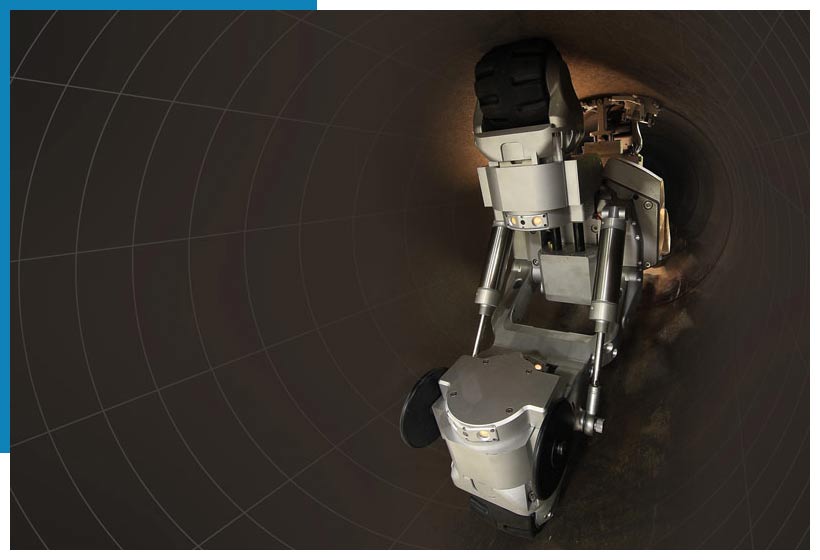

CIRRIS XI™ Inspection Robot

Home > Technologies > CIRRIS XI™ Inspection Robot

Technologies

CIRRIS XI™ Robotic Inspection of Large Diameter Cast Iron Gas Mains

The CIRRIS XI™ and CIRRIS XR® robots will give gas network operators an alternative to direct burial replacement by reducing pipeline risk and extending the usable life of large diameter (12″-48″) cast iron gas distribution mains.

The CIRRIS XI™ provides a means to assess the structural integrity of the pipe through measurements of wall thickness and stress to improve the way gas distribution utilities measure risk and ensure their assets are a good candidate for rehabilitation.

Key Benefits

Improve Risk Modelling

Data obtained through deployment of the CIRRIS XI™ robot will be fed directly into risk models so pipe risk can be measured using direct inspection data.

Ability to Deploy Sensors

Using sensors that are optimized for use in cast iron, the CIRRIS XI™ is able to measure wall thickness and determine if the pipe is under stress.

Enhance Public Safety

The data collected with the specialized sensors on the CIRRIS XI™ allows gas utilities to make better decisions about the outcome of their pipe; reducing risk and improving public safety.

Deployed into Live Gas Mains

The entire robotic pipeline inspection process is performed in live mains using a highly advanced no-blow launching system to minimize impact on local residents and businesses using gas on a daily basis.

Reduce Public Disruption

This technology is able to access over 1,000 ft (304m) of main through one small excavation to reduce the impact of utility maintenance typically seen with other methods.

Customizable Reporting

Our utility customers receive reports detailing the sensor data collected, in-pipe video and daily work reports. The main and features located inside the main are also provided.

CIRRIS XI

Pipeline Robotics Platform for Sensor Deployment

In-Pipe Sensor Deployment

The CIRRIS XI Robot can deploy sensors within pipeline environments to enable remote data collection from hard-to-access areas.

- Enables sensor deployment along all circumferential positions

- Can be customized to integrate various sensors

- Configuration allows the robot to navigate through bends and past common obstacles.

Deployment in Live Gas Pipelines

ULC Technologies brings years of expertise deploying complex robotics platforms into live gas mains. Sensor deployment in live environments reduces costs and minimizes public disruption.

Have a question or want to get involved?

Connect with our engineering team to learn more about CIRRIS XI.

Project Partners

Con Edison

Con Edison of New York provides electric service to approximately 3.5 million customers and gas service to approximately 1.1 million customers in New York City and Westchester County. The company also provides steam service in parts of Manhattan.

SGN

SGN manages the network that distributes natural and green gas to 5.9 million homes and businesses across Scotland and the south of England. Their dedicated and established innovation team manages ideas and opportunities, both from internal and external sources, co-ordinating their evaluation, and prioritising and converting into value propositions projects that align with their innovation strategy.

Related Projects

Explore What We've Done

|

Leading Development of Pipeline Robotics Since 2001

ULC Technologies is a leader in the development and deployment of pipeline robotic platforms. Learn how our CISBOT robots are deployed into live gas mains to extend the life of the pipe and reduce emissions.